John Pasley's Excellent Pulsed Power Overview

|

|||||||||||||

| Pulsed Power Switching

Devices - An Overview (Updated 02/08/18) By John Pasley, September 9, 1996 |

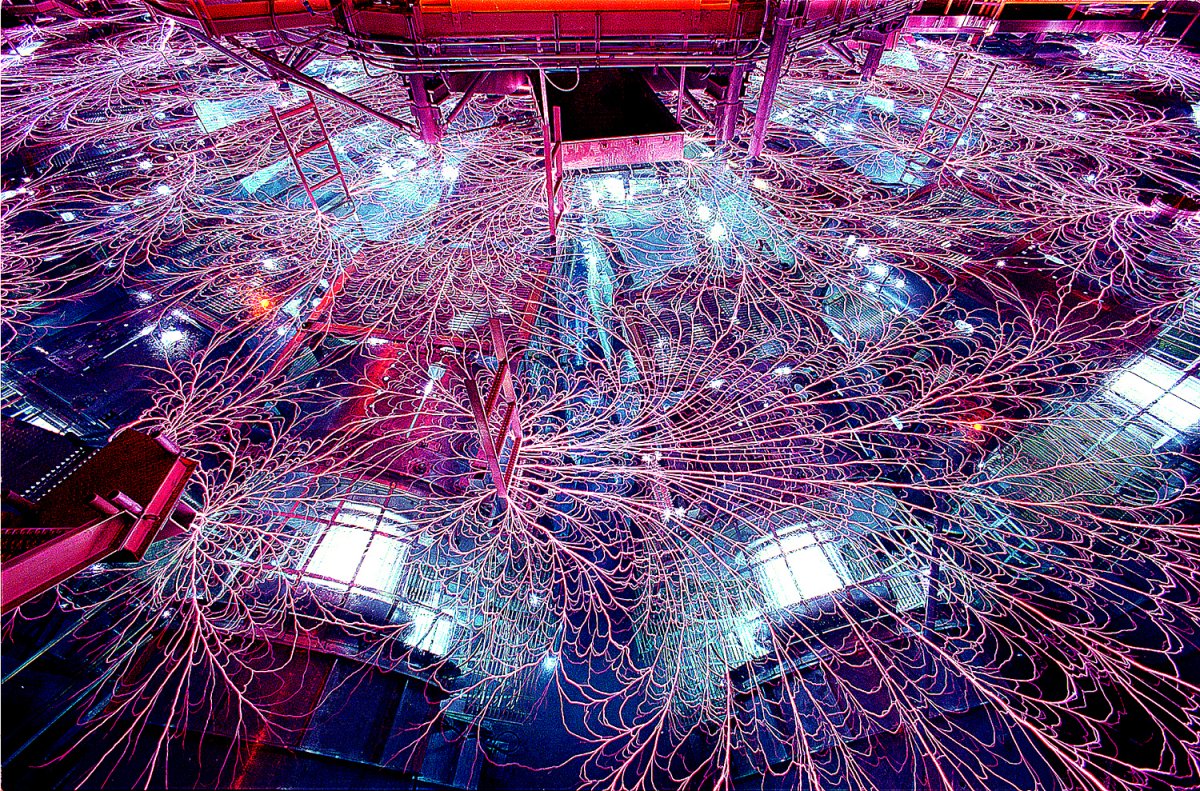

water's surface after a high-power "shot" at Sandia's awesome Z-Machine

By John Pasley, September 9, 1996

Copyright John Pasley 1996. This document may be freely distributed via. any means in part or in whole, however the author's name must be included and correctly attributed. The References Listed and The Disclaimer must also be included.

Foreword by Carey Sublette:An essential component of modern nuclear weapon technology is the ability to rapidly switch high voltage/high current electrical circuits at very high speeds.

The detonators that fire high explosive implosion systems (exploding wire or exploding foil detonators) require voltages in the range of (roughly) 2-20 kilovolts, a complete detonating system may draw currents ranging from 10 to 100 kiloamps. Pulse neutron tubes, used to precisely control the initiation of fission chain reactions, require voltages of 100 to 200 kilovolts, and currents in the ampere range. These currents must be turned on rapidly and precisely, timing accuracies of tens to hundreds of nanoseconds are required.

Switching devices that meet these stringent requirements often require specialized technologies or skills to manufacture. They are also dual use - in addition to weapons applications they have many civilian uses too. Examples include controlling flash lamps used in high speed photography or industrial photochemistry, generating high power radar pulses, in high energy physics laboratory equipment, to name but a few. Consequently commercial sale and international trade in these devices is permitted, but it is also regulated. Attempts to circumvent these regulations have gained considerable public attention in a number of technology smuggling cases in the 1980s and 90s involving one particular type of device - the Krytron. These devices have even appeared prominently in popular entertainment as the "McGuffin" used to drive espionage thrillers - like Roman Polanski's "Frantic". This article summarizes the basic technologies and devices, and their principle properties

Section 1.0: Introduction

Before entering into a consideration of the individual devices that concern us, it would be as well to explain some of the associated technology/ terminology.

1.1 Switching basics and terminology:

The switch is possibly the most elementary device in the field of electronics. A switch controls the flow of current in a circuit in a manner such that either the current flows at a value determined by the other components in series with it, or does not flow at all, as the case may be. However this ideal behavior is actually never exactly what is seen in real life. A switch has it's own parameters that determine how fast it can switch from open to closed, or how rapidly it can interrupt the flow of current once it is has been opened. Also of course there are more elementary considerations such as the current handling capacity of the switch and the peak voltage it can cope with before damage or other unwanted effects occur.Mechanical switches such as are common in the home are in actuality far from ideal in their behavior. The time taken to switch from off to on (the commutation time) is typically in the millisecond range. Also spurious effects such as bouncing may occur as the switch fluctuates rapidly from open to closed in the process of being physically manipulated by the operator.

Electromagnetic relays and reed switches experience similar problems to those seen in the humble light switch. Long commutation and switch bounce are standard features of virtually all mechanical switching devices.

With the advent of transistors and similar devices such as thyristors one would have thought that these slow switching problems would be things of the past. This is in fact largely true. But semiconductors are limited in other ways, it is very hard to find semiconductors capable of switching many kiloamperes especially at potentials in the kilovolt region, and those devices that can manage high currents such as the larger thyristors are troubled by overly high commutation times. Whilst there are now semiconductors coming onto the market capable of performing at these extremes of current and voltage there are some requirements which put even these devices to shame. If you want to switch 50 kilo Amperes with a sub 20 nanosecond commutation time at 20kV you are going to be in trouble if you are relying on semiconductor technology. However there is an alternative class of devices that have been around long before the humble transistor came on the scene. You might think that vacuum tubes and similar are a thing of the past. But for problems of this magnitude they are the only things on the market that will do the job.

1.2 Vacuum and Gas filled switching tubes, introduction and terminology:

There are a great many different types of vacuum tube in existence, however it is possible to group tubes according to some fairly basic criteria. There are two primary distinguishing features, the source of free electrons within the device and the gaseous filling (or lack of it) within the tube envelope. The later of these two concepts we have already introduced by implication. A vacuum tube is a device with a vacuum (very low pressure gas) filling. And a gas filled device is, as the name would suggest, filled with gas that might be at a pressure somewhat above or below atmospheric. The type of gas used is also an important feature, particularly in switching tubes where a wide variety of fillings are encountered.The source of the free conduction electrons in the device may be either thermal such as a heated filament physically associated with the cathode of the device - a hot cathode, or alternatively a simple consequence of a high voltage gradient across the device, resulting in auto-emission from the cathode. A device employing this latter method is known as a cold cathode device. In high voltage switching the presence of high voltages, and hence the possibility of large voltage gradients within devices means that the cold cathode system, quite a rarity in most other types of tubes, is the norm rather than the exception.

Other important terms encountered in gaseous state switching tubes:

Delay time.

The delay time is the time taken between the application of a trigger pulse and the commencement of conduction between the primary electrodes.Jitter.

Jitter is the variation of time delay from shot to shot given similar electrical stimulus.Commutation time.

The commutation time is the time taken for the conduction to reach maximum once it has commenced. (i.e. From the time from the end of the delay time to the time at which the maximum level of conduction occurs.)It should be pointed out that none of the switching tubes we are about to consider look very much like the things in the back of an old radio set. Many are large, some exceptionally so. Also glass has largely given way to ceramic in the higher powered devices. Before you go down your local electronics shop or radio shack it should also be pointed out that many of these devices besides costing $100's (often $1000's) a piece, and are also largely unavailable to the general public due to their application in advanced missile and nuclear weapon technologies. Of these devices the most 'everyday' is the ignitron which finds much application in industrial welding situations.

The following devices are considered herein:

2.0 Vacuum and Gaseous State Switching devices

2.1 Introduction to Cold Cathode Trigger Tubes

2.2 The Krytron.

2.3 The Sprytron.

2.4 The Thyratron.

2.5 The Over Voltage Spark Gap.

2.6 The Triggered Spark Gap.

2.7 The IgnitronIn addition I will include a short section on some of the solid state devices that are finally beginning to fill the shoes of the above gaseous state device (to a very marginal extent in most cases).

2.0 Vacuum and gaseous state switching devices:

Most of the devices in this section switch by inducing an arcing process in a gaseous medium. I have included in the triggered spark gap section some mention of devices that actually use a liquid or solid substitute for the gaseous material that is the norm in triggered spark gaps.The process of arc formation is actually quite complex physically, and it will not be gone into in any depth. Anyone who wishes to look more deeply into this aspect of device operation may contact the author for some suggestions as to suitable text books for use in such study.

2.1 An Introduction to Cold Cathode Switching Tubes:

Cold cathode trigger tubes are physically small devices designed to switch impulse currents and voltages of relatively small amplitude. Usually they are intended, as their name suggests, to trigger other larger devices.Typically cold cathode trigger tubes are designed to switch pulses of a few hundred volts and a few hundred milliamperes. Most trigger tubes have three or four electrodes, anode, cathode (+ve and -ve terminals respectively), a trigger/control electrode and sometimes a priming electrode.

A trigger tube performs in a very simple manner akin to that of a triggered spark gap, excepting that usually the conduction is not by an arcing but glow discharge. The glow discharge is initiated when all of the following factors are present:

i) A sufficiently high voltage is present across the device

(between anode and cathode)

ii) A trigger pulse of sufficient amplitude is present at the trigger

electrode.

iii) The gas in the tube is primed.Cold cathode trigger tubes rely upon some external or internal source to ionize the gas suitably for conduction to commence (This is called priming). This means that in theory some of these tubes will only switch a minute or so after the application of a suitable triggering voltage to the appropriate terminal of the device when some natural source of ionizing radiation ionizes the gas (forming a plasma) and hence causes conduction to commence. The triggering is basically random- it is subject to huge statistical variation even in apparently similar environments. Some devices incorporate a suitably ionizing source to reduce the maximum possible time delay after trigger application considerably. This source may be an electronic, radioactive or photon source of some form or other. However even the standard commercial devices often display a large variation (up to and above an order of magnitude different) between devices fired in sunlight and darkness, a standard commercial tube Z900T for instance displays a 20us delay in day light and a 250us delay in darkness.

2.2 The Krytron:

Krytrons are a highly specialized variety of cold cathode trigger tube. They were one of the first products developed by the US based company EG&G. The Krytron has 4 electrodes, and is filled with a gas at low pressure. A Krytron is distinguished among cold cathode trigger tubes for a variety of reasons.The Krytron is designed to switch moderately high impulse currents (up to around 3kA) and voltages (Up to around 5kV) in an arc discharge mode, compare this with the usual glow discharge of the standard trigger tube. Also, and perhaps more importantly, the Krytron is able to turn on this arc discharge very rapidly, the reason being that it relies on an already present plasma to support the conduction, rather than waiting for the plasma to be formed as a result of priming etc. This plasma is created and sustained by a keep-alive current between the keep-alive electrode and the cathode of the device. When the trigger is applied under the conditions of a high anode to cathode voltage, this plasma forms an easy path for the main conduction between anode and cathode.

The fact that a conduction path is already established prior to triggering makes a huge difference in the commutation time of these devices compared to standard cold cathode trigger tubes. Commutation times below 1 nanosecond are achievable with Krytrons and the time lag between application of trigger and the commencement of switching may be less than 30ns with an optimized driver circuit. (Note this delay is largely due to the fact that the ionized path will need to spread from the keep alive terminal to the anode of the device) Compare this delay time to that seen in the standard trigger tube which is dependent upon many environmental factors and typically 3 or 4 orders of magnitude greater. Note that the variation in time delay exhibited by the krytron is almost totally independent of environment, however the time delay may be reduced up to a point with increasing trigger voltage. Likewise the commutation time is generally decreased if the rise time of the trigger pulse is also decreased. Given identical trigger pulses however a krytron will have a very similar time delay from one shot to the next. This variation is known as jitter and may be less than 5ns in optimal circumstances.

A Krytron contains a source of Beta radiation, Ni-63. The quantity in each device is less than 5 microcuries and presents no significant hazard. Usually the source is pulse welded to a piece of Nickel wire that is in turn welded to one of the electrode supports. The purpose of this source is to increase the reliability of the krytron by aiding the formation of the initial glow discharge between the keep alive and the cathode. This initial keep alive current is very much subject to environmental factors such as are seen in the formation of the glow discharge in standard trigger tubes. It is for this reason that a radioactive priming element is used, much as in the priming source employed in a standard trigger tube (which is also occasionally a radioactive source).

Krytrons typically come in a small glass envelope somewhat similar to a neon indicator bulb with more leads.

Krytrons require a high voltage pulse (500V to 2kV) to be applied to the trigger electrode to fire successfully. This pulse is almost always generated by a pulse transformer fired by a capacitor discharge in the primary (rather like a simple strobe tube firing circuit).

The krytron often has only a short life expectancy if used regularly (often as few as a couple of hundred shots) However when used within the appropriate parameters and well within the expected life time they are extremely reliable, requiring no warm up and being immune to many environmental factors to a large extent (e.g. vibration, temperature, acceleration).

These properties, combined with the small size make the krytron ideal for use in the detonating circuitry of certain types of missiles and smart bombs. The krytron may be used directly to fire a high precision exploding wire, or alternatively as part of the triggering circuitry for a triggered spark gap or similar ultra high current triggering device as used in exploding foil slapper type detonators and larger EBW circuits.

Krytrons are used in firing circuits for certain lasers and flash tubes and also in some pulse welding applications, often as triggering devices for other larger devices such as thyratrons and spark gaps.

2.3 The Sprytron:

The Sprytron, otherwise known as the Vacuum Krytron, is a device of very similar performance to the Krytron. Though it generally exhibits a somewhat lower time delay after triggering. The Sprytron is designed for use in environments were high levels of radiation are present. The sprytron is hard vacuum 'filled' device unlike the krytron which, as noted above contains a low pressure gas.The Sprytron has only three leads, (no keep alive), but is otherwise very similar in outward construction to the Krytron. The reason for the use of a vacuum filling is almost certainly that there is no medium present for radiation from the external environment to ionize (such ionization could promote spurious triggering effects.)

The Sprytron requires a more powerful trigger pulse than the Krytron, as the device works by forming an arc directly between the trigger and the cathode, which causes the tube to breakdown (go into conduction) by disrupting the field between the anode and cathode.

A Sprytron is triggered in a similar fashion to Krytron, but as mentioned requires a higher energy trigger pulse and therefore a more powerful trigger transformer etc. EG&G makes trigger transformers optimized for use with their various tubes, and also make devices named Krytron-Pacs which incorporate a gas filled krytron and trigger transformer in a single housing.

One final point. It is interesting to note that in application circuits (references 1 and 4) the sprytron is always shown directly switching a load (an Exploding bridge Wire.) and a Krytron is always shown triggering a secondary device such as a triggered spark gap.

2.4 Thyratrons:

Thyratrons come in several varieties. All work similarly to the semiconductor Thyristor, one difference being that in many designs (Hydrogen Thyratrons are a common exception) the gate must be biased highly negative in the off state and then biased positive to achieve switching. Like Thyristors, Thyratrons operate like a latching switch, i.e.. once you have turned them on you can only turn off by cutting the supply to the main circuit. Mercury filled Thyratrons are the slowest, least useful type and are much more restricted environmentally than other types due chiefly to problems with the mercury condensing . They are rarely used as they have few advantages of the thyristor. Hydrogen Thyratrons are *much* faster switching than Thyristors. Some can achieve commutation in under 20ns. Inert gas fillings tend to offer superior performance compared to mercury filled devices, without matching the speed of the Hydrogen filled devices.Note that Hydrogen Filled Devices employ a hot cathode. The actual Physical construction/ operation of the thyratron is quite complicated compared to the other devices we have looked at and no attempt will be made to explain it's operation. The reader is advised to consult a wide range of books as devices employing different fillings, or electrode heating methods operate differently. It is not considered to be especially important to consider all these variations here as this is merely an overview of these devices and is not intended to be the final word on the subject. However, in order to differentiate the thyratron form other similar devices and to define it in at least some physical manner here follows Frungel's (Ref.4) definition of the device:

By the term 'thyratron' there is meant a discharge chamber in which are arranged a cathode, one or several grids, and an anode, and which is filled with an inert gas or metal vapor.'

Some Thyratrons can handle up to 50kV(double gap types) switch thousands of Amperes and handle very high power outputs( e.g. CX 1154 can handle peak powers of 40MW). Typical applications are Radar pulse modulators, Particle accelerators, Lasers and high voltage medical equipment. Another variety of thyratron is filled with Deuterium. These Deuterium filled devices are similar to their Hydrogen filled counterparts but the sparking potential for Deuterium is higher thus allowing even higher voltages to be handled. E.g. E3213 can switch 70kV (double gap type). Specialist Thyratrons with ceramic and metal bodies are encountered. These are designed to be used in extreme environmental conditions. There is a wide variety of grid configurations seen in Thyratrons, it would be impractical to consider them all here. Manufacturers of Thyratrons Include EG&G, GEC, English Electric Valve Co.Ltd, M-O Valve co. LTD. Big Thyratrons often require you to get a big box full of driver/control circuitry. Prices vary from a couple of dollars to thousands. Hot and cold cathode type devices are encountered.

Note these ratings are the exception rather than the rule in Thyratron devices, devices designed for sub kilovolt voltages and only capable of handling a few tens of amps pulsed are common enough.

Thyratrons typically come in either small multi- pin base type packages such as are common in other vacuum tubes or in the case of the higher current devices large tubular packages with hefty end connectors.

2.5 The Over Voltage Spark Gap:

The Over voltage spark gap is essentially just two electrodes with a gap between. When the voltage between the two electrodes exceeds the breakdown voltage of the gas, the device arcs over and a current is very rapidly established. The voltage at which arcing occurs in these devices is given by the Dynamic Breakdown Voltage, which is the voltage at which the device will breakdown for a fast rising impulse voltage. Note that this voltage may be as much as 1.5 times greater than the static breakdown voltage (breakdown voltage for a slowly rising voltage.) how much greater than the static breakdown voltage the actual breakdown voltage is will be depends almost entirely on how rapidly the voltage rise, a shorter rise time means a higher breakdown voltage. Commutation times for these devices are exceptionally low (sometimes less than 1 nanosecond).Over-voltage gaps are primarily used for protection. But in combination with the other devices mentioned here they are commonly used to sharpen the output pulses (decrease the rise times) of very high current pulses form triggered switching devices e.g. Thyratrons.

The size of these devices is almost entirely dependent upon how much current/voltage they are intended to switch, There is really no limit as to the size of these devices they can be as small as krytrons, however they can also be very big, and devices intended to switch MA will be just that.

2.6 Triggered spark gaps:

The triggered spark gap is a simple device, a high voltage trigger pulse applied to a trigger electrode initiates an arc between anode and cathode. This trigger pulse may be utilized within the device in a variety of ways to initiate the main discharge. Different spark gaps are so designed to employ one particular method to create the main anode to cathode discharge. The different methods areas follows-Triggered spark gap electrode configurations:

- Field distortion: three electrodes; employs the point discharge (actually sharp edge) effect in the creation a conducting path

- Irradiated: three electrodes; spark source creates an illuminating plasma that excites electrons between the anode and cathode.

- Swinging cascade: three electrodes; trigger electrode nearer to one of the main electrodes than the other.

- Mid plane: three electrodes; basic triggered spark gap with trigger electrode centrally positioned.

The triggered Spark gap may be filled with a wide variety of materials, the most common are-

- Trigatron: trigger to one electrode current forms plasma that spreads to encompass a path between anode and cathode.

1) Air

2) SF6

3) Argon

4) OxygenOften a mixture of the above materials is employed. However a few spark gaps actually employ liquid or even solid media fillings. Solid filled devices are often designed for single shot use (they are only used once- then they are destroyed) Some solid filled devices are designed to switch powers of 10 TW (10 000 000 000 000 Watts) such as are encountered in extremely powerful capacitor bank discharges. Except (obviously) in the case of solid filled devices, the media is usually pumped through the spark gap. Some smaller gaps do not use this system though.

Usually Gas filled spark gaps operate in the 20-100kV / 20 to 100kA range though much higher power devices are available. I have one spec for a Maxwell gas filled device that can handle 3 MA - that's 3 Million Amperes! But then it is the size of a small car!! More commonly gas filled devices have dimensions of a few inches. Packages are often shaped like large ice pucks though biconical, tubular and box like structures are also seen.

Sparkgaps are often designed for use in a certain external environment (e.g., they might be immersed in oil). A system for transmitting the media to the appropriate part of the device may sometimes be included. Common

environments used are:a) Air

b) SF6

c) OilTypical spark gap device no.'s are: TG7, TG113, TG 114 etc., etc.

Spark gaps are damaged by repeated heavy discharge. This is an inevitable consequence of such high discharge currents. Electrode pitting being the most common form of damage. Between 1 and 10 thousand shots per device is usually about what is permissible before damage begins to severely degrade performance.

EG&G make miniature triggered spark gaps specially designed for defense applications. these devices are physically much smaller than normal spark gaps (few cm typical dimensions) and designed for use with exploding foil slapper type detonators.

Laser switching of spark gaps. The fastest way to switch a triggered spark gap is with an intense pulse of Laser light which creates a plasma between the electrodes with extreme rapidity. There have been quite a few designs employing this method, chiefly in the plasma research area.

Triggered spark gaps tend to have long delay times than Thyratrons (their chief competitor, at least at lower energies) However once conduction has started it reaches a peak value exceptionally rapidly (couple of nanoseconds commutation.)

2.7 Ignitrons:

The ignitron is mercury vapor rectifier in which an arc is switched between a (usually graphite) anode and a mercury pool cathode. The discharge is initiated by an ignitor electrode which dips into the mercury pool cathode. On application of a suitable impulse current/voltage to this ignitor an electron emitting source is formed at the point at which the ignitor contacts the pool. This initiates the arcing between the anode and cathode.It is important that the ignitor should be triggered correctly. The ignitor requires a certain energy for successful ignition and also an 'ignitor characteristic' application of this energy in terms of current and voltage with respect to time. Misfiring or ignitor damage will otherwise occur. It is also vital that no significant negative voltage should appear at the ignitor with respect to the cathode else ignitor destruction will be the inevitable result.

There are two main ways by which the trigger can be biased:

Anode excitation: common in resistance welding applications here the anode bias is connected to the ignitor by means of a switch (thyristor, thyratron etc.) and a resistor/fuse network. The ignitor current drops rapidly on ignition as the anode-cathode voltage drops very low during conduction.Separate excitation: as the name suggests, here the ignitor circuit is largely independent of the main circuit.

Ignitrons are often used in parallel for AC power control applications.

Ignitrons must often be cooled when used continuously (i.e.. Not single shot as in capacitor discharge) Water cooling is commonly employed. It is vital that Ignitrons must be used in the correct temperature range to hot or too cold can be very bad news for these devices- (cold leads to mercury vapor condensing on the anode.)

Ignitrons are very limited with regards their physical orientation. This reason being simple that they rely upon a pool of liquid at one end of the device that must be correctly positioned for the ignitor to function correctly. Positioning the device so that it leans over at an angle of more than 2 or 3 degrees from the vertical is fatal.

Most ignitrons operate at most currents between 5 Amps and 100kA and may be suitable for voltages from a couple of hundred to 20 000 Volts.

Thyratrons and Krytrons are sometimes used in ignitron triggering circuits along with the familiar thyristor.

Ignitrons are suited to applications were power control of high voltages or currents is required. Welding is probably the most common application.

3.0 Solid State Devices:

(Note this section may well be considerably expanded following further research by the author.)There are now a few commercially available transistors on the Market which can switch many tens of kV. There are also a few transistors about that can handle pulsed currents above 5kA. These devices may match for example Krytrons and Sprytrons in terms of electrical performance, but not in terms of size and (in the case of the Sprytron) radiation hardness.

Thyristors are widely available in designs that can handle upwards of 10kA pulsed at several kV. They are however very slow switching devices and are not capable of achieving even low microsecond switching speeds.

A new class of devices is at present showing great promise in the R&D sector. These devices are optically (usually LASER) switched devices employing GaAs or Diamond film technologies. The reader is advised to consult the appropriate reference below for more information relating to these devices.

Final note to the reader:

Some of the devices I have mentioned are subject to strict control due to their military applications. None of the above information is however in any way restricted or controlled. For clarity switching devices that are restricted by dual use guidelines are as follows: (courtesy Oak Ridge National Laboratory)(a) Cold-cathode tubes (including gas krytron tubes and vacuum sprytron tubes), whether gas filled or not, operating similarly to a spark gap, containing three or more electrodes, and having all of the following characteristics:

1. Anode peak voltage rating of 2500 V or more,

2. Anode peak current rating of 100 A or more,

3. Anode delay time of 10 microsecond or less, and(b) Triggered spark-gaps having an anode delay time of 15 microsecond or less rated for a peak current of 500 A or more;

(c) Modules or assemblies with a fast switching function having all of the following characteristics:

1. Anode peak voltage rating greater than 2000 V;

2. Anode peak current rating of 500 A or more; and

3. Turn-on time of 1 microsecond or less.Acknowledgments:

I would like to thank the following for their help and assistance:

Carey Sublette for providing a great deal of help and encouragement.

Roy Schmaus for providing the original site for this information.References: (in alphabetical order by title)

1) EG&G Catalogues/ Material. (RE: Components)

2) Exploding Wires Vol. 4, Proceedings of 4th Conference on Exploding Wire Phenomena. Ed. Chace and Moore - Plenum Press (RE: EBW's)

3) High Power Optically Activated Solid State Switches, ed. Rosen And Zutavern- Artech House (RE: Solid state devices)

4) High Speed Pulse Technology by Frank Frungel -Academic Press. (RE: EBW's, FCG's, components)

5) High Velocity Impact Phenomena by Ray Kinslow-Academic Press. (RE: Foil Slappers)

6) IEEE publications (please contact author for more details).

7) Maxwell Catalogues. (RE: spark gaps)

8) Mullard Valves and Tubes Book 2 Part 3 (RE: components)FURTHER INFORMATION PERTAINING TO THE SUBJECT MATTER WILL BE MUCH WELCOMED BY THE AUTHOR.

Information regarding the author: I am not an expert in any of the above technologies and I will welcome any corrections. However please could anyone providing information also provide references to either the material they present or as to themselves so that their contribution may be given due weight.

Disclaimer:

I the author assume no responsibility for anyone who injures/kills themselves trying to implement any of the above technologies. High voltages are generally exceptionally dangerous, and none of the above is intended or should be used to provide instruction in the correct procedures for building or constructing high voltage circuitry of any description. High voltage is used here to describe any voltage which may cause death (i.e., anything above 50V).

Some Other Places to Visit:

|

|

|

|

|

| Tesla Info Center |

"Quarter Shrinker" |

More Arcs & Sparks |

Get Shrunken Coins! |

Get a Lichtenberg! |